TT Talk - Automation is now an option for all ports

Automation has been proven beyond doubt to improve port performance and enable cargo to be moved more safely, securely and sustainably. There are now more than 50 automated container terminals globally (Figure 1) and big advances continue to be made in port automation technologies. As such there is now a strong case for operators of the remaining 95% of the world’s terminals which are not yet automated to consider becoming so.

![Figure 1 - Number of automated container terminals by region [Statista] Figure 1 - Number of automated container terminals by region [Statista]](/fileadmin/uploads/tt-club/Photos/TT_Talk_images/Figure_1_-_Number_of_automated_container_terminals_by_region__Statista_.png)

Figure 1 - Number of automated container terminals by region [Statista]

Certainly, the concept of Spain’s Ports 4.0 initiative, which involves a digital transformation of the country’s ports, is gaining traction worldwide. This includes the use of advanced analytics, artificial intelligence and the ‘internet of things’ to create highly efficient and flexible logistics hubs. Successful implementation of these technologies leads to increased competitiveness, improved sustainability and continued technological advancements in the maritime industry.

Automation in ports and terminals can create new technology-based roles, such as remote operators and technical support. It can also open up the transport and logistics industry to a more diverse workforce, attracting people who may have been excluded due to the physical demands of the workplace.

As well as large container terminals, automation is a growing trend throughout the ports sector, driven by the need to optimise performance and minimise environmental impact. This article explores the key aspects of port automation, including innovative technologies, opportunities, benefits and challenges.

Innovative port automation technologies

There are several automation technologies now available for transforming port operations.

Robotic cranes and automated guided vehicles (AGVs) are now used around the world for efficient loading and unloading of containers. These technologies have the capability of increasing the speed of operations and minimise the risk of accidents.

The development and implementation of autonomous ships for transport and logistics are revolutionising the maritime industry. These ships can navigate and operate without human intervention, leading to safer and more efficient maritime operations.

Smart logistics and predictive analytics are data-driven technologies that can optimise supply chain management, enhance overall port efficiency, forecast demand, identify potential bottlenecks and improve decision-making processes.

And virtual replicas of port infrastructure, known as digital twins, allow for testing and optimisation of operations. Simulating scenarios such as extreme weather or ship collisions can prepare ports for real-world challenges.

Opportunities for port process automation

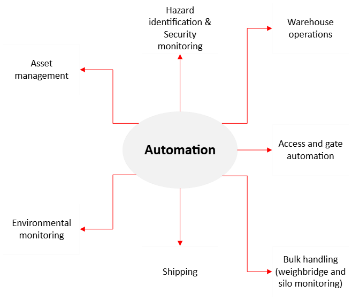

In addition to container handling, there are now a wide range of other port processes to which automation can be applied (see Figure 2).

Figure 2 - Process automation opportunities

Effective asset management is crucial for the smooth operation of automated ports. Automated systems can manage the entire lifecycle of port assets, from procurement and operation to maintenance and disposal. This helps in balancing costs and performance, reducing business continuity risks and ensuring the longevity of port infrastructure.

Automatically identifying and mitigating hazards is essential for maintaining safety in automated ports. Technologies such as video analytics and real-time monitoring systems can detect potential hazards, such as equipment malfunctions or unauthorized personnel in restricted areas.

Security is a critical aspect of port automation. Advanced security monitoring systems, including surveillance cameras, access control systems and cybersecurity measures help in protecting port infrastructure and assets from threats such as theft, sabotage and cyberattacks. Continuous monitoring and real-time alerts ensure a swift response to security incidents.

Automation in warehouse operations enhances efficiency and accuracy in handling cargo. Automated storage and retrieval systems, robotic palletisers and conveyor systems streamline the movement of goods within the warehouse. These technologies can minimise errors and improve inventory management.

Automated access and gate systems improve the flow of vehicles and cargo in and out of the port. Technologies such as automated gate systems, RFID tags, and biometric access control ensure secure and efficient entry and exit of vehicles and personnel. These systems reduce congestion, enhance security and improve overall operational efficiency.

Automation in bulk cargo handling involves the use of automated loaders, unloaders, and conveyor systems to handle bulk materials such as grain and minerals. These technologies increase the speed and efficiency of bulk cargo operations and minimise the risk of accidents.

Finally, environmental monitoring is essential for ensuring sustainable port operations. Automated systems can monitor air and water quality, noise levels and energy consumption in real time. These systems help to identify and mitigate environmental impacts, ensure compliance with regulations and promote sustainable practices.

Benefits and challenges of automation

The adoption of automation technologies in ports offers several benefits:

- Increased efficiency: automation enables faster turnaround times, reduced congestion and improved overall productivity. Automated systems can operate continuously without breaks, leading to higher throughput and better utilisation of resources.

- Improved safety: automation reduces the risk of accidents and enhances worker safety. Automated systems can handle hazardous tasks, minimising the exposure of workers to dangerous conditions.

- Environmental sustainability: automation contributes to cleaner and more sustainable port operations through optimised energy use and reduced emissions.

Despite the numerous benefits, port automation also presents challenges:

- Training: automation is likely to generate new roles within the organisation. Ports must invest in training programmes to ensure that workers can adapt to the new technologies.

- Initial implementation costs: the investment in automation can be significant. Ports need to carefully plan and manage these investments to ensure a positive return on investment.

- Operational challenges: integrating automation systems and ensuring smooth operation can be complex. Ports must address issues such as data standardisation, system interoperability and handling exceptions.

Conclusion

Port automation is revolutionising the maritime industry by enhancing efficiency, reducing operational costs and improving safety. While there are challenges associated with initial costs and operational complexities, with careful planning these can often be overcome. The future of port automation is bright.

If you would like further information, or have any comments, please email us, or take this opportunity to forward to any others who you may feel would be interested.

Documents

TT Talk Edition 320 (Chinese) (534 kB) 07/04/2025

- Date

- 11/03/2025